Non-Contact Type Measuring Instrument

Price 17000.00 INR/ Piece

Non-Contact Type Measuring Instrument Specification

- Usage

- For Electronics, research labs, material analysis,

- Material

- Metal And Plastic

- Product Type

- Measuring Instruments

- Application

- Industrial

- Weight

- 50-80 Grams (g)

Non-Contact Type Measuring Instrument Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Non-Contact Type Measuring Instrument

Features of Non-Contact Type Measuring Instrument :

- Excellent performance

- Rustproof body

- Sturdy construction

- Clear display

Advanced Measurement Technology

Utilizing the latest non-contact sensing techniques, this instrument provides accurate measurements without physically touching the sample. Ideal for analyzing fragile electronics or sensitive materials, it reduces the risk of contamination and preserves sample integrity. The robust structure ensures stability, while its lightweight design facilitates easy handling in laboratory or industrial settings.

Versatility Across Applications

Whether used for research, industrial inspection, or electronics evaluation, this measuring instrument adapts to a range of scenarios. Its construction from metal and plastic enhances both durability and resilience, making it a reliable tool for consistent, long-term use. Users benefit from rapid results, reduced errors, and ease of integration into existing testing workflows across diverse industries.

FAQs of Non-Contact Type Measuring Instrument:

Q: How does the non-contact measuring instrument work?

A: The instrument utilizes optical or electronic sensors to measure dimensions, thickness, or other properties of materials without making direct physical contact, ensuring fast and precise results.Q: What materials is the instrument made from, and why?

A: It is constructed from a combination of metal for strength and plastic for reduced weight, making it durable yet easy to handle during extended use.Q: When should this instrument be used instead of a contact-type device?

A: It is best used when measuring fragile, hazardous, or contamination-sensitive materials, as the non-contact operation prevents damage or interference with the sample.Q: Where can this measuring instrument be utilized effectively?

A: The device is ideal for electronics manufacturing, research labs, material analysis facilities, and general industrial quality control within India.Q: What is the usage process for this instrument?

A: Simply position the instrument near the material to be measured, activate the device, and view results on its displayno physical contact or sample alteration is required.Q: What are the main benefits of choosing a non-contact measuring device?

A: It offers enhanced accuracy, faster measurements, protects sensitive samples, and minimizes instrument wear, resulting in long-term reliability and reduced maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Temperature Measuring Instruments Category

IR Thermometer

Price 7000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 200800 Grams (g)

Product Type : Thermometer

Material : Metal And Plastic

Usage : For Electronics, research labs, material analysis,

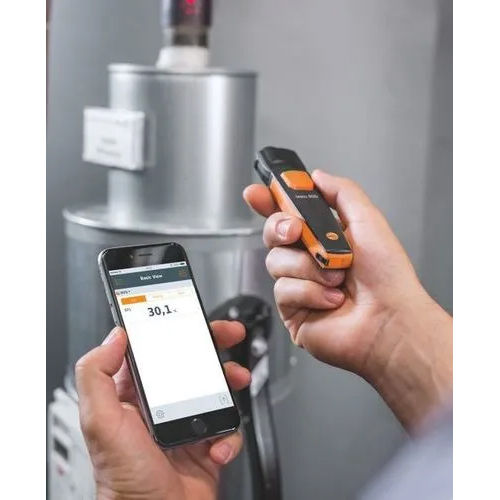

Thermometer Smart and Wireless Probe

Price 4000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 200500 Grams (g)

Product Type : Thermometer

Material : Metal And Plastic

Usage : For Electronics, research labs, material analysis,

Infrared Thermometer

Price 13000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 200500 Grams (g)

Product Type : Infrared Thermometer

Material : Metal And Plastic

Usage : Industrial

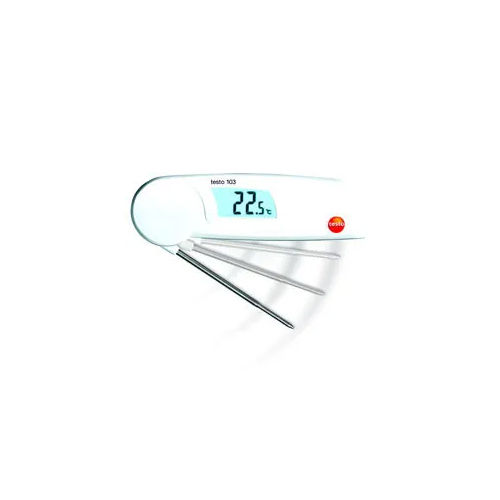

Contact Type Measuring Instruments

Price 11500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 100300 Grams (g)

Product Type : Measuring Instruments

Material : Metal And Plastic

Usage : For Electronics, research labs, material analysis,

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry